How do you know if electron beam crosslinking is right for you?

For more than 40 years, we’ve seen what works — and what doesn’t — when it comes to wire and cable performance. One technology that’s been trusted again and again is electron beam (E-beam) crosslinking. It’s not new, it’s not experimental — it’s a proven process that can transform the durability, reliability, and value of your product.

At its core, E-beam crosslinking uses high-energy electrons to permanently “lock” the polymer chains in cable insulation and jacketing. This changes a standard thermoplastic into a thermoset — a material that won’t melt, deform, or crack when heat, chemicals, or mechanical stress pile on. The result? A cable that’s made to last, even in the toughest environments.

Performance That Pays Off

We’ve worked with manufacturers and end users who’ve pushed E-beam crosslinked cables to their limits. Here’s what they consistently see:

- Higher thermal endurance: Continuous operating temps of 150–200 °C versus 90–110 °C for uncrosslinked cables.

- Better chemical resistance: Survives contact with fuels, oils, and solvents that would quickly damage standard insulation.

- Stronger mechanically: Resists abrasion, cut-through, and deformation.

- Longer service life: 2–5× longer in harsh conditions — fewer replacements, less downtime.

Manufacturing Advantages You Can Measure

E-beam isn’t just about performance in the field — it can also make your production process leaner:

- Faster throughput: Crosslinking in seconds instead of hours.

- Smaller footprint: A modern E-beam line can fit in ~2,000–3,000 sq ft — often replacing multiple ovens and ventilation systems.

- Lower energy use: No high-temperature ovens means big savings on energy and HVAC costs.

- Continuous power supply: consistent power delivery for consistent throughput

- Simpler process: No chemical crosslinking agents, no post-curing wash, no hazardous waste.

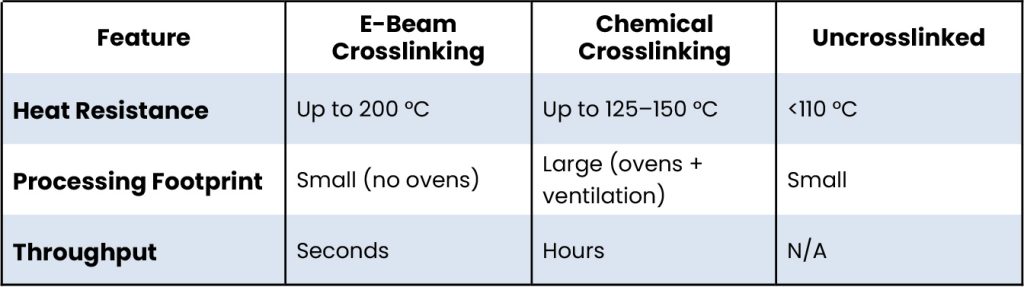

Comparison Table

Cost Impact Over Time

Yes, E-beam equipment is a capital investment — but it’s one that pays back in multiple ways:

- Reduced operating costs: Lower energy consumption, less scrap.

- Material flexibility: Use standard polymers and still hit high-performance specs.

- Customer satisfaction: Longer-lasting cables mean fewer warranty claims.Example: A plant producing 10 million feet of medium-voltage cable annually could save hundreds of thousands of dollars in energy and maintenance over the equipment’s life — while boosting throughput.

Where E-Beam Excels

You’ll find Wasik E-beam processed cables in:

- Automotive & EV: Under-hood wiring, charging cables, high-voltage harnesses.

- Aerospace & Defense: Lightweight, flame-resistant wiring for confined spaces.

- Industrial & Mining: Power and control cables that stand up to moisture, abrasion, and chemicals.

- Renewables: PV and offshore wind cables exposed to UV, ozone, and temperature extremes.

In Summary

We’ve seen E-beam make the difference between “good enough” and “built for anything.” It delivers better thermal, chemical, and mechanical performance while streamlining manufacturing and lowering lifetime costs. If you’re ready to explore what it could mean for your operation, we’re here to talk through the details — and show you what the numbers look like for your product line.