The Accelerator is the heart of the E-beam system. All other assemblies are supporting it.

The Accelerator is the heart of the E-beam system. All other assemblies are supporting it.

At Wasik, we will design and manufacture a system to meet your requirements. Currently, our custom systems offer the following options:

- Voltage – 300kV to 1.0Mev

- Current – 25mA – 100mA

- Scan Horn – 18” – 72”

- Shielding – Self-Shielding or Concrete Bunker

- Under-Beam Handling – Custom designed to meet specific requirements for Self-Shielded Units

- Accelerators – single or dual

Our Turnkey Solution

The original founder of Wasik worked closely with the inventor of electron beam technology in the 1950s and since, has been a premier provider of E-Beam processing technology. With our decades of experience, Wasik can walk you through every step of your e-beam process. Our institutional knowledge helps us design solutions with ease and confidence. Our customers gain from our experience and view us as a trusted industry resource.

Our turnkey solution typically takes 6-10 months from start to finish depending on the scope and scale of your project.

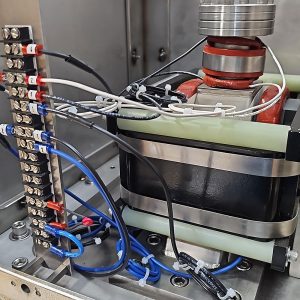

The Power Supply creates the high voltage required to accelerate electrons. Wasik’s is the simplest and most robust power supply in the industry.

The Power Supply creates the high voltage required to accelerate electrons. Wasik’s is the simplest and most robust power supply in the industry. The Power Cabinet distributes all high voltage three-phase electricity, protecting workers and operators.

The Power Cabinet distributes all high voltage three-phase electricity, protecting workers and operators. The Control Cabinet is the main operator interface, where recipes, interlocks, data acquisition, and remote access for support are accessed.

The Control Cabinet is the main operator interface, where recipes, interlocks, data acquisition, and remote access for support are accessed. The scan system, along with the waveform generator, spreads out the electron beam making it useful as a processing tool. It bends and scans the beam, effectively creating a curtain for a useful and efficient processing area.

The scan system, along with the waveform generator, spreads out the electron beam making it useful as a processing tool. It bends and scans the beam, effectively creating a curtain for a useful and efficient processing area. The Ultra-High Vacuum System maintains the required high vacuum to allow the free movement of electrons.

The Ultra-High Vacuum System maintains the required high vacuum to allow the free movement of electrons. Shielding design meets and exceeds all regulations, allowing for easier staffing, compared to environments that require a radiation-certified operator.

Shielding design meets and exceeds all regulations, allowing for easier staffing, compared to environments that require a radiation-certified operator. Under-Beam Handling moves the product to be processed through the electron beam.

Under-Beam Handling moves the product to be processed through the electron beam.